InvenTide helps you predict demand, optimize inventory, and streamline supply operations—so you can improve service levels, reduce working capital, and respond faster to disruptions.

We build forecasting models that learn from your historical sales, seasonality, promotions, pricing, lead times, and external signals to produce accurate SKU/location/channel-level predictions—plus confidence ranges for better planning.

We translate demand forecasts into practical inventory decisions: safety stock, reorder points, service-level targets, and allocation rules across warehouses and locations—reducing stockouts without overstocking.

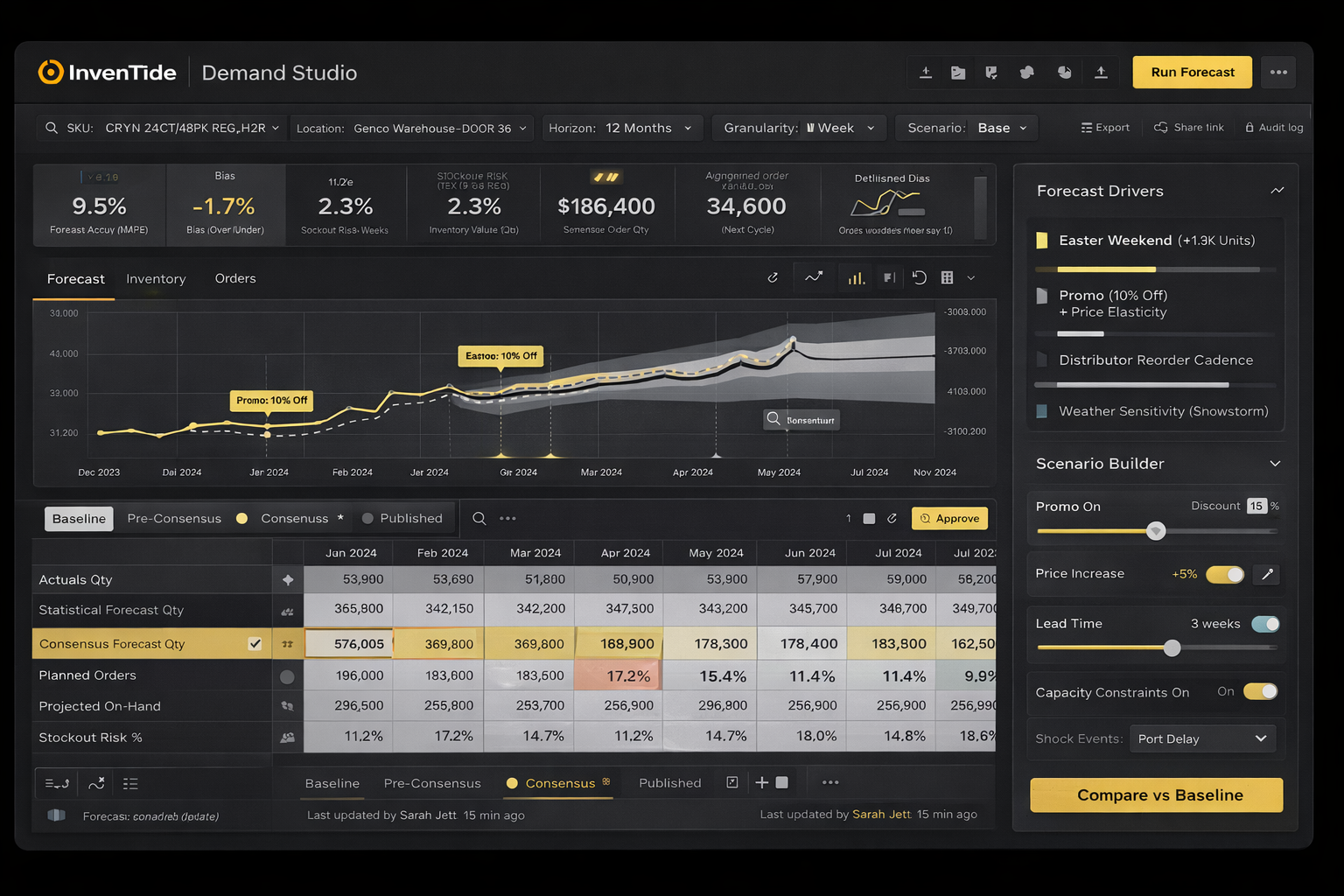

We create decision-support models and dashboards that connect demand to capacity, procurement, and production constraints—making Sales & Operations Planning faster, clearer, and far more scenario-driven.

We optimize the flow of goods end-to-end: network design scenarios, lane and mode selection, shipment consolidation, routing logic, and on-time delivery analytics—turning logistics data into measurable cost and performance gains.

AI Demand Prediction for a Canadian Manufacturer

The client was planning production and purchasing using spreadsheets and “tribal knowledge.” That worked—until it didn’t. Demand spikes around holidays and regional events were causing two expensive problems at the same time:

InvenTide built a demand prediction application that combined historical sales patterns with real-world drivers that were previously ignored.

We started by consolidating and cleaning data sources:

We delivered a production-grade Demand Prediction Application with:

Within the first planning cycles, the client moved from reactive firefighting to proactive planning:

InvenTide Inc. — Lightweight computer vision models, deployed at the edge.

We build efficient AI that runs close to the source—on cameras, gateways, and embedded devices—to deliver real-time detection, classification, and anomaly monitoring with minimal latency. Our solutions are designed to reduce cloud dependence, lower computational overhead, and stay reliable in real-world conditions—factory floors, hospitals, vehicles, warehouses, and remote sites.

At InvenTide, we apply vision and edge AI across industries to automate inspection, improve safety and compliance, enable smarter tracking and monitoring, and unlock predictive insights from visual data. Every engagement is tailored: we start from your operational constraints, design models that fit your hardware, and deliver deployable systems that integrate cleanly into existing workflows—built for measurable impact, not demos.